Small Elongation Strapping

-Composite Cord Strapping are manufactured from high tenacity, strongest synthetic fibers embedded in a polymer coating. It has the same breaking intensity as steel strapping. It is quickly replacing steel banding as a safe, cost effective and environmentally friendly method of securing loads in many industrial applications.

Product Description

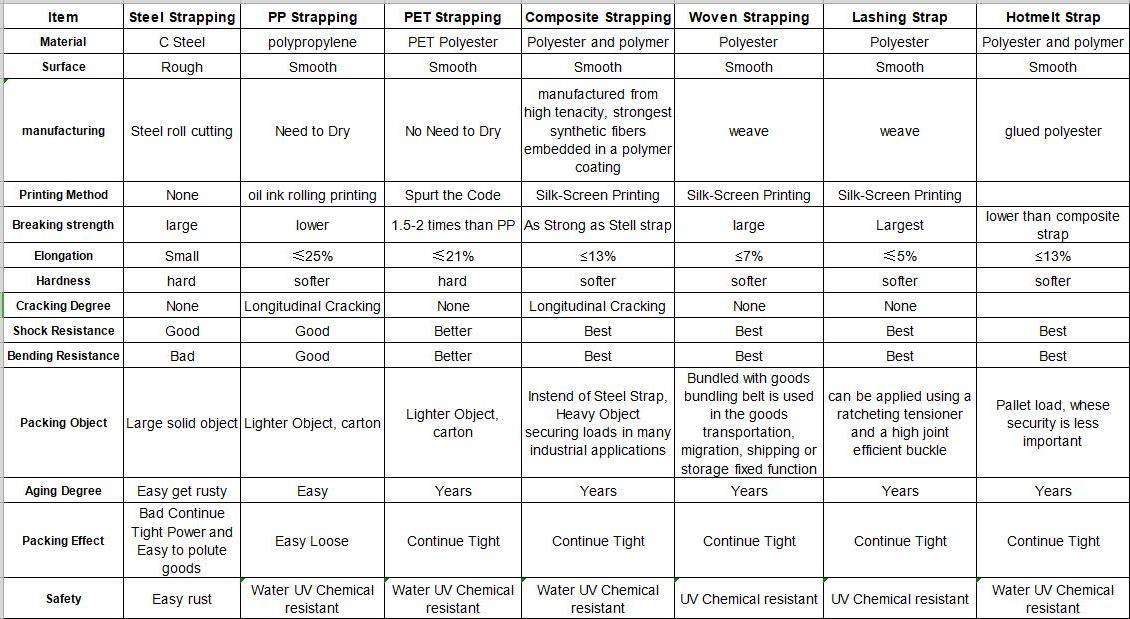

Among all the strappings, PP strapping has the highest elongation which is 25%, followed by PET strapping with elongation of 21%. Composite strapping and hot melt strapping have the same elongation, it is 13%. For woven cord strapping, the elongation is 7%. Lashing strap’s elongation is 5% and steel strapping’s elongation is the lowest.

When we bundle the goods, a suitable strapping elongation is necessary to ensure the safety of the goods.

If strapping’s elongation is too high, it would not fasten continuously and become loose so the goods could not be safely packaged.

If strapping’s elongation is too low, it could break instantly during the moving and the goods could not be protected effectively.

To achieve the best effect, the strapping should have a certain elongation which is not too high and not too low so that it would not loose and would not break.

Composite cord strapping, hot melt strapping and woven cord strapping have this performance. They are perfect packaging materials.