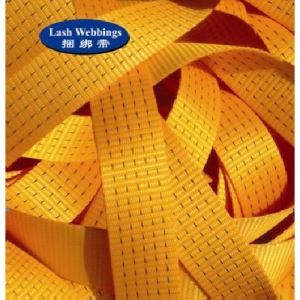

Tie Down Webbing

Qingdao Strapping Pack Co.,Ltd.( Qingdao X&H Webbing Co.,ltd.) specialize in manufacturing and exporting a range of quality tie down webbing and is a specialist in cargo securement solutions in china. Our tie down webbing, including our low elongation range, is manufactured to meet the...

Qingdao Strapping Pack Co.,Ltd.( Qingdao X&H Webbing Co.,ltd.) specialize in manufacturing and exporting a range of quality tie down webbing and is a specialist in cargo securement solutions in china. Our tie down webbing, including our low elongation range, is manufactured to meet the strict local and international standards for use with tie down hardware to secure cargo or equipment during road, rail or sea transit.

The use of quality tie down webbing - also known as ratchet strap webbing or lashing webbing, along with the correct cargo securement system, is vital to the safety of the operator and the prevention of possible cargo damage that can occur during transit.

Webbing Products manufactures an extensive range of LIGHTWEIGHT TIE DOWN WEBBING AND INDUSTRIAL TIE DOWN WEBBING

High quality materials and superior manufacturing processes allow for a world-class product performance which is supported by quality management system, vigorous in-house testing as well as industry testing facilities. This ensures compliance to stringent quality standards and peace-of-mind to our customers. Comparative testing confirms the superior performance of the tie down webbing and its performance criteria when measured against the relevant specifications.

Accreditation: Webbing Products is ISO9001-2015,CE,GS,DNC-GL certified, with its quality management system being key to producing high quality products for global supply.

Our cargo securement webbing (lashing) ranges are manufactured from ultra-high tenacity polyester yarns, utilising compact weave patterns to provide superior system strengths, while remaining durable and versatile.

Our specialist range of tie down webbing commences at break strengths from 250 kg up to 15,000 kg; differentiating break strengths are identified by the use of identity lines and colour coding to customer specifications

Specialised finishing equipment is used to create our webbing’s low elongation characteristics, which are specifically designed to afford very little load movement

The melting point of the polyester utilised is 260°C; working temperatures range from -20°C to 150°C, with peaks up to 200°C; polyester is durable, abrasion and water resistant and resistant to ultra violet (UV) light

Lightweight polyester webbings are further designed to provide resistance to mould, mildew, rotting and shrinking, making this the right decision and long lasting choice for outdoor usage such as tent straps, open top containers, roof racks and bicycle securing.

Webbing is normally supplied in 100m rolls with personalised printing and branding available upon request. Longer lengths are available on special order

Advantages:

♦ Low elongation

♦ Superior strength factors

♦ High abrasion resistance

♦ UV resistance

♦ Low water absorption and chemical resistance

♦ Ease of use

♦ Cut resistant – certain products

Applications:

♦ Ratchet tie down straps–from light to heavy duty

♦ Cam, winch, tent straps etc.

♦ Securing cargo for transit

♦ High abrasion applications

♦ Furniture manufacture and transport

Witdth: 10mm--100mm

Breaking Strength: 250kg--15,000kg

Thinckness: 0.5mm--3mm

Elongation: ≤7%