In fact, when the use of plastic packaging belt, its main knot pattern mainly have two kinds. One is hot melt, the other is the use of plastic packaging buckle, in fact, this way of hot melting than the steel buckle simple, and use up, it will be better, mainly by the way of hot melt to make plastic packing belt knot together, forming a whole.

If the equipment is not external energy, so when used to use the plastic packaging buckle. Plastic packing belt with high strength, good toughness, more wear-resistant, but the use of plastic packaging belt is afraid of squeezing and impact. Once the plastic packing belt is squeezed or folded, it is easy to bend into two parts, seriously affecting the quality of packaging. If the transport process is not careful, there may be a fracture phenomenon. Such items scattered on the road is a bit more than the candle.

Related News

- Useful Life Of Composite Strapping

- A Guide To Cargo Strapping

- Everything You Have To Know About The Strapping

- The Maintenance Of Lashing Straps

- Benefits Of Composite Strapping

- Advantages Of Using Polyester Composite Strapping

- What Is Composite Strapping?

- Do You Know Polyester Strapping?

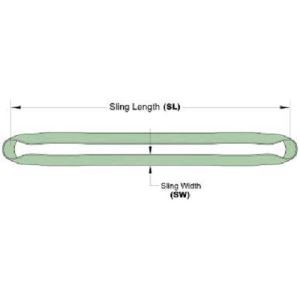

- Polyester Flat Webbing Sling With Soft Eye Protection

- Woven Vs. Composite Strap

- Polyester Strapping Vs Steel Strapping

- Polyester Lashing Strap Was Containerized And Ready To Be Ship To Germany

- Metal Serrated Seals

- Cord Strap And Buckle