1. High strength: Plastic packing Belt material is polyester polyester) has a very strong tensile resistance, close to the same specifications of the steel belt, the common plastic belt several times.

2. High toughness: Because the plastic packing belt has the plastics characteristic, has the special flexibility, the elongation rate reaches 12% in the transportation process may prevent the bump to cause the packing belt break.

3. Safety: Plastic packing belt without sharp edge of steel belt, will not cause damage to the wrapped object.

Packaging and unpacking will not cause injury to the operator and prevent all unsafe factors.

4. Adaptability: Plastic packing belt due to material and production process factors, can be suitable for all kinds of climate change, high temperature resistance, moisture resistance, not like the steel belt damp rust and loss of tensile resistance, bundle strength attenuation small.

5. Convenient and environmental protection: because of the light-weight plastic packing belt, easy to carry, small size, save the warehouse space, used pet belt convenient recovery, in line with environmental requirements. 6 Economic benefits Good: Plastic Packing belt density only for the steel belt density of 1/6 unit length of the price is relatively low, 1 tons of steel belt length equivalent to 6 tons of strip length, and the interest rate per meter is lower than the steel belt

Related News

- Useful Life Of Composite Strapping

- A Guide To Cargo Strapping

- Everything You Have To Know About The Strapping

- The Maintenance Of Lashing Straps

- Benefits Of Composite Strapping

- Advantages Of Using Polyester Composite Strapping

- What Is Composite Strapping?

- Do You Know Polyester Strapping?

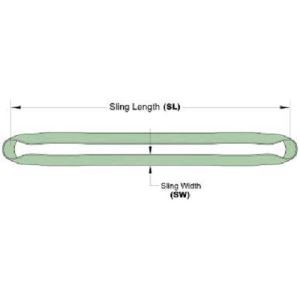

- Polyester Flat Webbing Sling With Soft Eye Protection

- Woven Vs. Composite Strap

- Polyester Strapping Vs Steel Strapping

- Polyester Lashing Strap Was Containerized And Ready To Be Ship To Germany

- Metal Serrated Seals

- Cord Strap And Buckle